B100

Solutions for Railways

About the project

The pilot project biojazda.sk was launched by the Slovak road haulier Yellow Express in April 2021, when it launched with first runs of a new truck — a Scania unit adapted for low-emission operations using 100 % biodiesel fuel (B100). In April 2024, the Envien Group company RT Logistic also joined the project, fuelling its ČKD 740 series locomotive with the same type of fuel. This marked the beginning of testing a cleaner freight and rail transport alternative that could be implemented immediately. Compared to fossil fuels, the key advantage of B100 lies in its greenhouse gas emissions, which have been proven to be 70 per cent lower. The B100 fuel is supplied by another Envien Group company, Meroco, a regional producer of sustainable biodiesel. In rail transport, B100 presents a viable alternative to fossil diesel on rail lines where electrification is not economically feasable.

Why did we launch the Biojazda.sk (Bioride) campaign?

With its current renewable energy sources, Slovakia needs a significantly higher share of biofuels in transport to meet the ambitious European greenhouse gas emissions reduction targets. Through this information campaign promoting the B100 Project success story, we are able to demonstrate that goals to meet the renewables energy targets in transport, using fuels with high biofuel content and achieving the CO2 reduction targets, are not only possible, but realistic.. This initiative also highlights that that biofuels have the potential to become the most cost-effective solution to today’s energy and environmental problems.

How long does the pilot project last, and what does it aim to achieve?

We have been monitoring our experimental type ČKD 740 locomotive (HDV 740 T448.0948 series), running on B100 fuel, since April 2024 under regular operating conditions at the premises of our partner, Envien Group. This project is scheduled to continue through 2025, during which the reliability of the siding operation, fuel consumption and service intervals will be monitored. As of the first couple of months of testing, we have not experienced any operational issues. B100 fuel consumption is comparable to that of B7 and routine maintenance, such as fuel filter replacement, has shown no significant differences. Based on our testing experience so far, we do not anticipate that long-term use of B100 will lead to increased costs related to any unanticipated technical issues. Currently B100 is not used in rail transport in Slovakia The objective of this project is to provide a comprehensive evaluation of its practical application in this sector. By introducing this type of fuel into rail transport, we could provide Slovak carriers with a low-emission alternative which can be used on the routes where electrification is not economically viable. In addition to freight and passenger operators, this fuel could in the future also be used by industrial enterprises operating non-electrified rail lines – such as ours. Also, replacing fossil diesel with biodiesel would improve the internal ESG scores.

We are the first to conduct this type of testing in Slovakia: the pilot project will be evaluated after one year of continuous operation and testing.

How can B100 fuel reduce CO2 emissions compared to diesel over its entire life cycle?

B100 fuel is a fully renewable fuel produced from vegetable oils or used cooking oil – a waste raw material effectively repurposed in this process. Emissions of conventional (fossil) diesel account for 95.1 g CO2/MJ, while the emission footprint of biofuel produced from vegetable oil or waste raw materials (used cooking oil) is 33 g CO2/MJ or even 9 g CO2/MJ. B100 fuel’s contribution to emission reduction is significant, curbing as much as 90 % CO2 emissions when derived from waste oil compared fossil fuel.

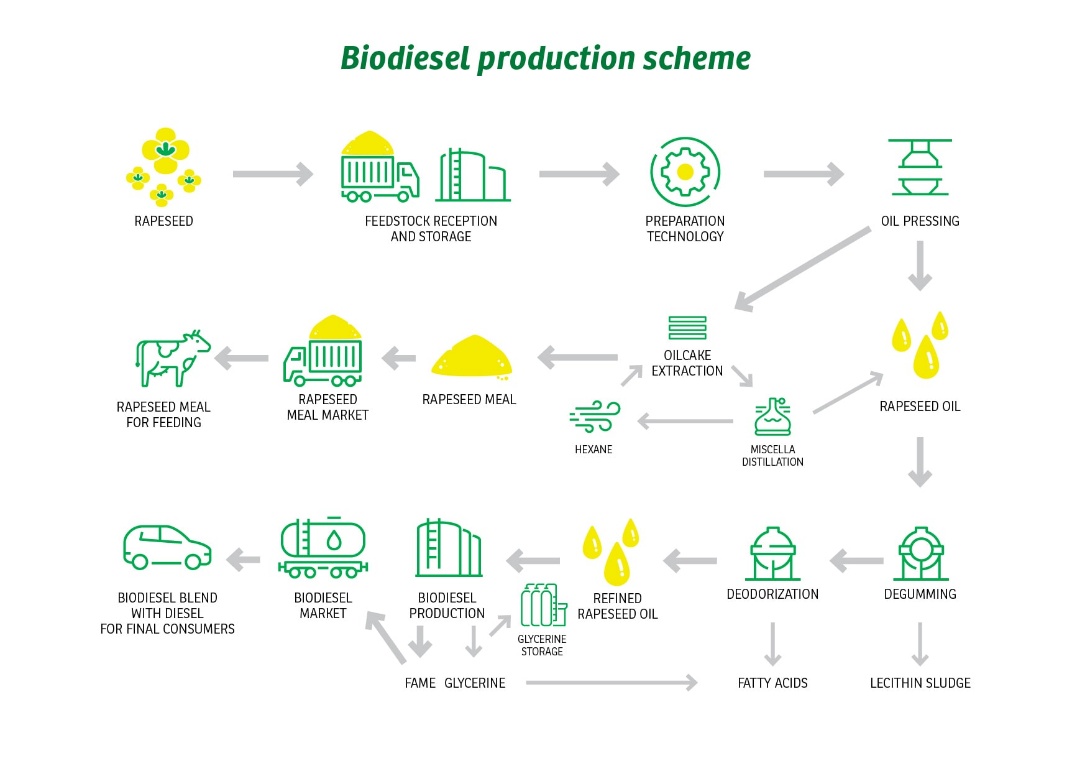

Biodiesel from rapeseed oil – an ecological and sustainable approach

Some of the information floating around about rapeseed being grown in monoculture fields in order to support biofuel production is not entirely accurate. Under good farming practice, rapeseed is never cultivated in monoculture – this is neither possible nor desirable. European agricultural commodity production is known for its strict sustainability requirements. In Slovakia, rapeseed for food, cosmetics, or biofuel production, is grown on only 3.1% of the country’s territory – that is 6.5 % of the total agricultural land.

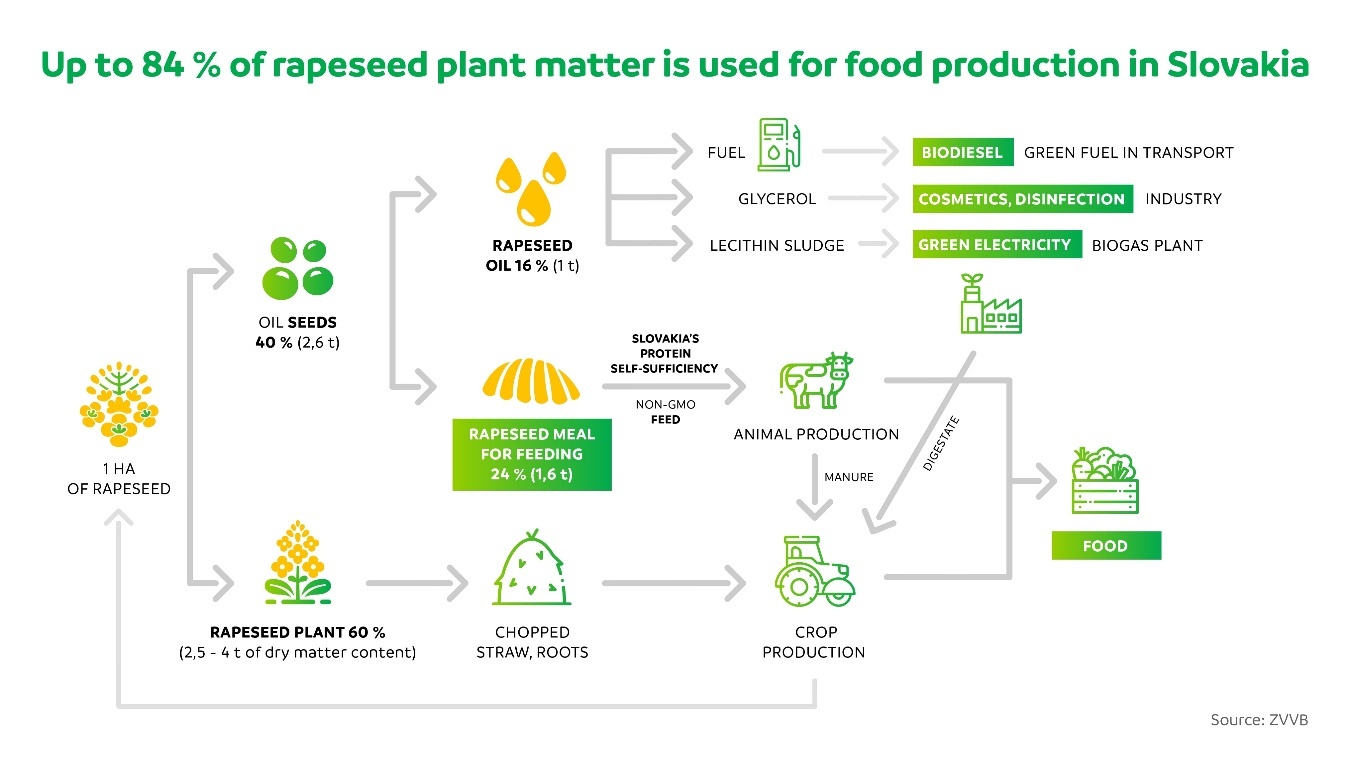

(Bio)fuels versus food

Only a small part of the rapeseed plant is used for biodiesel production. After oil pressing, more than half of the processed mass remains in the form of rapeseed meal (with high protein content, up to 35 %). This locally produced feed (suitable for all livestock thanks to the balanced ratio of nutrients) can effectively replace imported soybean meal that mostly contains GMO. Although almost unknown to the public, in this way biofuel production contributes significantly to EU's protein self-sufficiency. At the same time, there is important research currently underway to evaluate the use of proteins of rapeseed origin in human food.

More biofuels do not require more cropland

Increasing the share of biofuels in Slovakia would not require expanding the areas planted with rapeseed or corn. The country already produces a sufficient volume of biofuels to support a potential increase, were such plans ever to materialize. Therefore, a shift toward greater biofuel use can be achieved without putting additional pressure on agricultural land.

Did you not find the answer to your question? Are you interested in learning more? Are you considering implementation of biodiesel in your company fleet?

Write to us at info@biojazda.sk or use the contact form below.