B100

Solution for your road freight transport

Our Project

The pilot project of biojazda.sk was started by the Slovak road freight carrier Yellow Express in April 2021, with the first Slovak journey of a brand new Scania truck adapted for low-emission driving utilizing only B100 fuel, containing nothing but 100% biodiesel. This implementation brought about a cleaner freight transport alternative that can be immediately implemented, with a proven greenhouse gas reduction of 70%. The regional biofuel producer Meroco, a member of Envien Group in Slovakia, is a B100 fuel supplier, producing 100% biofuel in a sustainable manner.

This alternative has proven promising for emission reduction in road freight transport, so there was no hesitation adding additional such trucks to the fleet, meeting a growing interest in providing green services.

Why did we launch the SK-Bioride / Biojazda.sk campaign?

Even though Yellow Express had an eminent interest in greening the vehicle fleet in an economically viable and sustainable way through a long-term feasible solution, the fact is that without more road freight operators like Yellow Express, Slovakia cannot meet its commitment to use 14% of its energy consumption from renewable energy sources (RES) by 2030, so the share of biofuels in transport must increase significantly.

So this information campaign on the B100 Project success story serves as a basis for proving that goals to meet the RES share in transport, using fuels with a high share of biofuel and achieving the set CO2 reductions, are reachable targets, and that biofuels have the potential to become the cheapest solution for the current energy and environmental problems.

How long did the pilot project run, and what is being monitored?

We monitored a vehicle running on B100 fuel since April 2021 in standard traffic conditions. During the year of testing, the biodiesel Scania truck successfully reached a distance of almost 94,700 km, 70% of it carrying a full load and 30% empty. The average fuel consumption of the vehicle was 29.5 L/100 km, or 0.82 L/t*100km. The vehicle was refueled at the biorefinery premises of the Meroco plant in Leopoldov, Slovakia. As expected, greenhouse gas emission reductions of up to 70% were reached during the performed tests.

Based on the results achieved, we can assume that the B100 alternative is highly effective and suitable for Slovak roads and can be implemented immediately thanks to local production of biofuels in Slovakia. Thus, the operator Yellow Express decided to expand its fleet by additional Renault trucks running on B100 fuel, setting a good example and inspiring other road freight carriers aiming at ecological fleet renewal.

What is the contribution of B100 fuel compared to diesel fuel for CO2 emission reduction considering life cycle assessment?

B100 fuel is a fully renewable fuel produced from vegetable oils or used cooking oil – a waste raw material valorized in this way. Emissions of conventional (fossil) diesel account for 95.1 g CO2/MJ, while the emission footprint of biofuel produced from vegetable oil or waste raw materials (used cooking oil) is 33 g CO2/MJ or even 9 g CO2/MJ. B100 fuel’s contribution to emission reduction is therefore great, with as much as 90% CO2 emissions reduction if B100 fuel from waste oil is used.

Where can B100 fuel be refueled?

Currently, it is commercially possible to refuel only B7 blended fuels, containing a 6.9% share of biodiesel. However, we believe that the pilot project’s successful results and the support of the state could mean we can prove this solution’s efficiency, aiming to create economically suitable conditions for an affordable and ecological alternative that will appeal to other road freight operators. The addition of a B100 refueling dispenser to existing filling stations can thus become a desirable and simple solution compared to other alternatives. There is a simple option to provide a storage tank with refueling equipment to the premises of interested companies, as common practice currently implemented in many fleets.

What kind of engine does a Scania truck use for 100% biodiesel?

The vehicle's engine is basically a diesel engine being fully adapted to process B100 fuel with no need for extra addition of any fossil fuel. The Scania truck was purchased by Yellow Express directly from a Swedish manufacturer producing this type of biofuel engine. However, there are also other manufacturers of trucks, cars, buses, and even tractor engines worldwide that produce a variety of engines running on 100% biofuels, whether based on biodiesel or bioethanol.

How do biofuels work in an automotive engine?

Biofuels, as well as fuels containing bio-components, are produced according to ISO, EN, and ASTM technical standards, accepted globally by engine manufacturers. All motor vehicle manufacturers state in their vehicle documentation whether biofuels can be used and the maximum blend ratio acceptable for an individual vehicle. Currently, it has been proven that for all vehicles, running on conventional B7 diesel with blended biodiesel does not affect the operation or the lifespan of the engine. Biodiesel has a high lubricity, which reduces engine wear and does not cause pollution.

Experience from the B100 truck’s home country – Sweden

"At Scania we have been driving the shift towards sustainable transport for a number of years and one of the ways we do that is by providing trucks that can run on high quality 100% FAME fuel. Over the past five years we have delivered over 5000 vehicles capable of 100% FAME operation all over the world, over half of those in Europe. All renewable fuels are needed to make an impact on the transport sector’s transition to fossil free operation and 100% FAME fuel provides a way to reduce carbon emissions quickly and efficiently. Feedback from B100 customers is very positive. Not only are the trucks performing according to expectations for their transport mission but the benefit of using locally produced fuels with high savings on CO2 emissions is helping the environmentally focused transport buyers and trucks operators to meet their internal CO2 goals.”

Lampros Prentzas, Scania, Sweden

Application of clean biofuels for trucks worldwide

Sweden is an ambitious country in terms of climate action known for continuously introducing alternative sources for road and urban public transport. With the support of B100 fuel, Stockholm already became a non-fossil fuel traffic city in 2020. Lisbon, Graz in Austria, and Grodzisk Mazowiecki in Poland, as well as some American cities then followed this positive example. Oleo100 fuel (i.e. B100 fuel) is available only for fleet operators in France, while in Sweden it is widely distributed among the population.

Conclusions

The truck running on B100 fuel has proven to be competitive with conventional fuel trucks. During the operation it required no additional service/maintenance or costs that would disadvantage B100 operation, prompting an increased interest from clients with strong demands for green solutions.

For commercial deployment it will still be necessary for legislation on biofuels excise tax to take into account their low greenhouse gas emissions. Today, the excise tax is set such that it is highest when biofuels (which have lower greenhouse gas emissions than pure fossil fuels) are converted to energy and greenhouse gas emissions – this is contrary to the state’s commitments and intention to reduce greenhouse gas emissions in transport. The price of pure biofuel (B100) must represent an incentive: to motivate customers it must be lower than or at least the same as the price of B7 diesel.

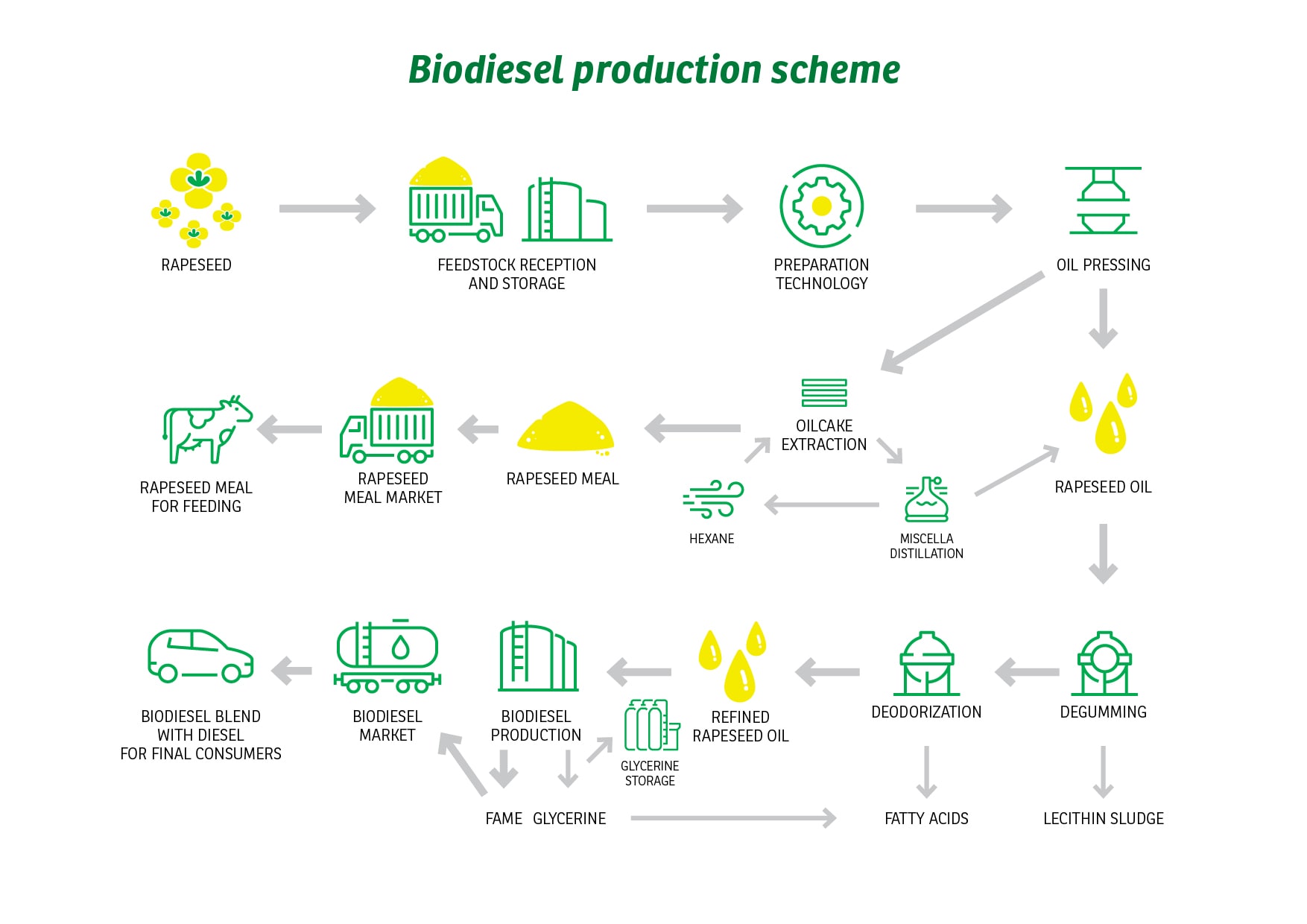

Biodiesel production from rapeseed oil – ecological practice with sustainability

Statements about rapeseed monoculture fields to supply biofuels production are not accurate. Under good farming practice, rapeseed is never grown as a monoculture – this is neither possible nor desirable. The European production of agricultural commodities is known for its strict conditions to assure the highest level of sustainability. Rapeseed for all purposes (including food or cosmetics) is grown in Slovakia on only 3.1% of its territory, i.e. 6.5% of its total agricultural land.

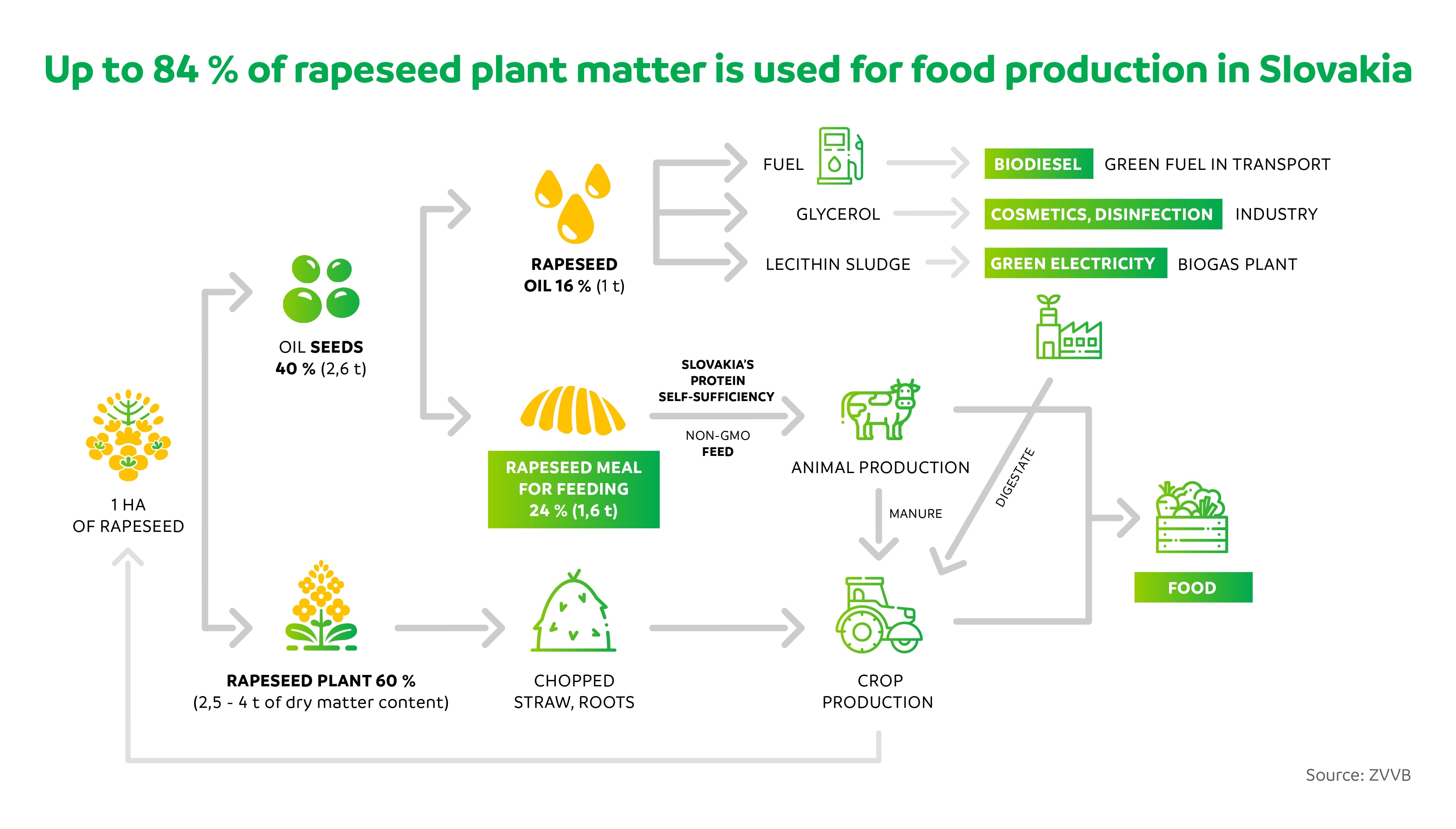

(Bio)fuels versus food

Only a small part of the rapeseed plant is used for biodiesel production. After oil pressing, more than 50% of the processed mass remains in the form of rapeseed meal (with a high protein content – up to 35%). This locally produced feed (suitable for all livestock thanks to the balanced ratio of nutrients) can effectively replace imported (mostly GMO) soybean meal. Although this is almost unknown to the public, in this way biofuel production contributes significantly to the EU's protein self-sufficiency. At the same time, currently there is important research underway to evaluate the use of proteins of rapeseed origin even in human nutrition.

More biofuels do not mean more land sown

The sowing areas for rapeseed or maize would not have to be increased even when a higher proportion blend of biofuels to fossil fuel is introduced in Slovakia. The current production of biofuels in Slovakia is already sufficient, and the volume of biofuels can ensure such plans are met.

Did you not find the answer to your question? Are you interested in learning more? Are you considering implementation of biodiesel in your company fleet?

Write to us at info@biojazda.sk or use the contact form below.